-

Feed de notícias

- EXPLORAR

-

Páginas

-

Blogs

-

Fóruns

Global Pipe Coatings Market Strategic Analysis

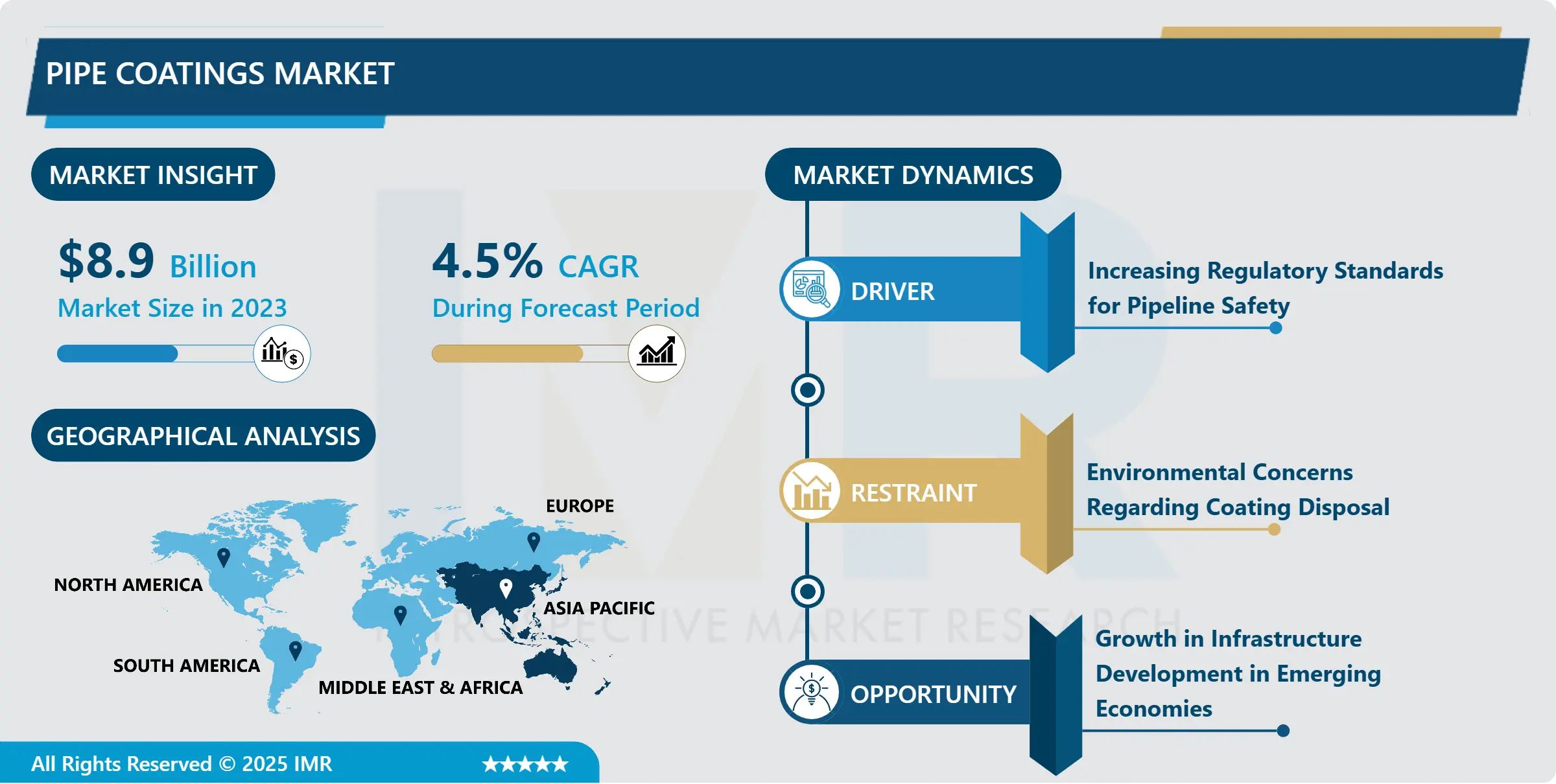

The Global Pipe Coatings Market Size Was Valued at USD 8.90 Billion in 2023 and is Projected to Reach USD 13.22 Billion by 2032, Growing at a CAGR of 4.50% From 2024-2032.

Pipe coatings are specialized protective layers applied to the internal or external surfaces of pipes to safeguard them against corrosion, abrasion, and chemical attacks. These coatings, which include fusion-bonded epoxy (FBE), polyethylene, and polyurethane, are vital for maintaining the structural integrity of piping systems used in harsh environments. By creating a robust barrier between the pipe material and its surroundings, these coatings significantly reduce the risk of leaks and catastrophic failures in critical infrastructure.

The primary advantage of modern pipe coatings over traditional unprotected systems is the dramatic extension of asset life and the reduction in long-term maintenance costs. These coatings offer superior resistance to cathodic disbondment and environmental stress cracking, ensuring consistent flow efficiency. Major industries utilizing pipe coatings include oil and gas (for offshore and onshore pipelines), water and wastewater treatment, chemical processing, and mining. As global energy demand rises and aging water infrastructure requires modernization, high-performance pipe coatings are becoming the industry standard for safe and sustainable fluid transportation.

👉 To request a sample report:

https://introspectivemarketresearch.com/request/20229

Market Segmentation

The Pipe Coatings Market is segmented into Type, Surface, and End-User Industry. By Type, the market is categorized into (Fusion Bonded Epoxy (FBE), Polyethylene (PE), Polyurethane (PU), Concrete Weight, Others). By Surface, the market is categorized into (External Surface, Internal Surface). By End-User Industry, the market is categorized into (Oil & Gas, Water & Wastewater, Chemical Processing, Mining, Others).

Growth Driver

The principal growth driver for the Pipe Coatings Market is the massive expansion of oil and gas pipeline networks, particularly in North America and the Middle East. As exploration and production activities move into deeper offshore waters and more corrosive shale environments, the demand for high-performance external and internal coatings has intensified. These coatings are essential to prevent the corrosive effects of sour gas and crude oil, ensuring the safe transport of hydrocarbons over thousands of miles. Furthermore, the global push to replace aging municipal water infrastructure with corrosion-resistant piping is fueling a steady increase in coating application volumes across urban centers.

Market Opportunity

A major market opportunity lies in the development of "Smart Coatings" integrated with sensing technologies for real-time health monitoring of pipelines. Historically, pipeline integrity was checked through periodic physical inspections, but the emergence of nanotechnology-enhanced coatings allows for the detection of early-stage corrosion or stress before it becomes visible. Additionally, there is a lucrative niche in the expansion of eco-friendly, solvent-free coating formulations. As environmental regulations tighten globally, manufacturers that offer low-VOC (Volatile Organic Compound) and high-solids coatings will gain a competitive edge in catering to the sustainable infrastructure requirements of modern chemical and water treatment plants.

Detailed Segmentation

Title: Pipe Coatings Market Market, Segmentation The Pipe Coatings Market is segmented on the basis of Type, Surface, and End-User Industry.

Type

The Type segment is further classified into Fusion Bonded Epoxy (FBE), Polyethylene (PE), Polyurethane (PU), and Concrete Weight. Among these, the Fusion Bonded Epoxy (FBE) sub-segment accounted for the highest market share in 2023. This dominance is due to the widespread adoption of FBE as a primary corrosion protection coating for steel pipes in the oil and gas industry. FBE provides excellent adhesion to the metal substrate and superior resistance to cathodic disbondment. Its ability to be applied in a controlled factory environment ensures high-quality consistency and durability, making it the industry standard for both small-diameter and large-diameter pipeline projects globally.

End-User Industry

The End-User Industry segment is further classified into Oil & Gas, Water & Wastewater, Chemical Processing, and Mining. Among these, the Oil & Gas sub-segment accounted for the highest market share in 2023. This dominance is attributed to the critical nature of hydrocarbon transport, where even minor corrosion can lead to significant environmental damage and financial loss. The sheer scale of cross-country pipeline projects and the harsh operational conditions of subsea pipelines necessitate high-performance coating systems. With the resurgence of midstream infrastructure investments to connect new production sites to refineries, the oil and gas sector continues to be the primary revenue driver for the pipe coatings market.

Some of The Leading or Active Market key Players Are-

· Akzo Nobel N.V. (Netherlands)

· PPG Industries, Inc. (United States)

· Sherwin-Williams Company (United States)

· Shawcor Ltd. (Canada)

· Axalta Coating Systems (United States)

· Arkema S.A. (France)

· 3M Company (United States)

· Jotun A/S (Norway)

· Wasco Energy (Malaysia)

· Tenaris S.A. (Luxembourg)

· Aegion Corporation (United States)

· BASF SE (Germany)

· and other active players.

Key Industry Developments

In June 2024, Akzo Nobel N.V. announced the launch of an ultra-durable powder coating designed specifically for high-temperature internal pipe environments. This news item is significant because it addresses the growing challenge of transporting hot fluids in industrial processing plants without degrading the internal coating. By providing a material that maintains its integrity at elevated temperatures, the company is helping operators reduce downtime and extend the life of specialized industrial piping.

In March 2024, Shawcor Ltd. unveiled an automated application system for dual-layer fusion-bonded epoxy (FBE) coatings. This news item marks a critical advancement in manufacturing efficiency, as the new robotic platform ensures more uniform thickness and reduces the risk of holidays (voids) in the coating. This innovation is designed to enhance pipeline safety by providing a more reliable barrier against soil stress and moisture in demanding onshore pipeline installations.

Key Findings of the Study

· Dominant Segments: Fusion Bonded Epoxy (FBE) and the Oil & Gas industry lead the market in terms of revenue and volume.

· Leading Regions: North America leads the market due to extensive shale gas exploration and a massive network of existing and new pipelines.

· Key Growth Drivers: Rising energy infrastructure investments and the need for modernization of aging water and wastewater systems.

· Market Trends: Increasing adoption of multi-layer coating systems (3LPE/3LPP) and the shift toward sustainable, low-VOC coating technologies.

🔍 𝐈𝐧-𝐃𝐞𝐩𝐭𝐡 𝐑𝐞𝐩𝐨𝐫𝐭:

https://introspectivemarketresearch.com/reports/pipe-coatings-market/

About Introspective Market Research

Introspective Market Research is a global provider of data-driven market intelligence and strategic advisory services. Our analysts and consultants deliver comprehensive reports, actionable insights and customized consulting to clients across chemicals & materials, healthcare, energy, environment, infrastructure, and advanced manufacturing sectors.

Media Contact:

Introspective Market Research.

Email: press@introspectivemarketresearch.com

Website: http://www.introspectivemarketresearch.com

Phone: +91-91753-37569