-

Ροή Δημοσιεύσεων

- ΑΝΑΚΆΛΥΨΕ

-

Σελίδες

-

Blogs

-

Forum

How Innovation Is Reshaping the US Aircraft Docking Systems Market

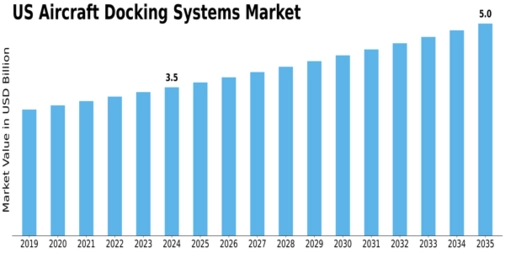

Innovation continues to redefine aviation infrastructure, especially in maintenance operations. The US Aircraft Docking Systems Market is witnessing remarkable upgrades in design and technology that enhance efficiency, precision, and safety in aircraft maintenance.

Market Growth and Design Transformation

New market growth trends reveal that maintenance facilities prefer modular docking systems that are quick to assemble and customizable. Lightweight aluminum alloys and composite materials are now replacing traditional heavy metals, offering strength with improved mobility.

Docking systems are also being developed with scalable designs, allowing maintenance teams to reconfigure structures based on the aircraft type. This adaptability supports multiple aircraft simultaneously in shared maintenance spaces.

Digital Integration and Automation

Advanced docking systems now include sensors, control panels, and motorized height adjustments. These smart integrations enable fine-tuned alignment with aircraft contours, reducing manual labor and ensuring precise positioning.

Automation improves maintenance accuracy, minimizes errors, and enhances worker safety. Such innovation reflects the overall modernization of maintenance hangars across the aviation sector.

Future Forecast

According to industry experts, market trends indicate increased adoption of data-driven systems that record maintenance performance metrics. The integration of AI and IoT could revolutionize how docking systems are monitored, maintained, and deployed.

FAQs

1. How does technology improve aircraft docking systems?

By integrating automation, digital sensors, and adjustable components that enhance safety and reduce manual errors.

2. Are modular systems better for maintenance?

Yes, they offer flexibility, reduce setup time, and improve efficiency for a range of aircraft models.